Aluminum Alloys

Information from Materials Standards for PM Structural Parts, 2024 Edition

published by Metal Powder Industries Federation

Overview

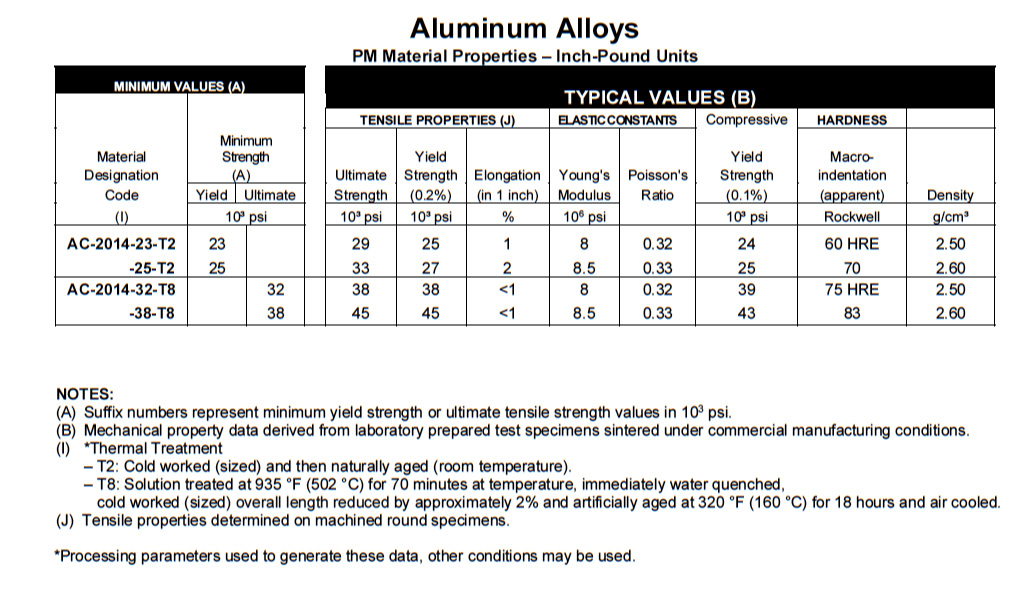

This subsection covers aluminum and aluminum alloys produced via the powder metallurgy process using admixed materials.

Material Characteristics

- Usage: PM aluminum parts are typically employed in structural applications where low weight is crucial.

- Density: The nominal density of PM aluminum parts is around 2.55 g/cm³ (94% relative density), which is approximately one-third the density of steel parts.

- Corrosion Resistance: PM aluminum parts exhibit excellent corrosion resistance and are often used without additional surface treatments. However, post-sintering operations like resin impregnation or anodizing can be performed for enhanced corrosion resistance or decorative finishes.

- Anodizing: Parts can be anodized to provide additional corrosion resistance and/or decorative surface finishes, offering a variety of color options.

- Aluminum-Copper Alloy System: The Al-Cu alloy system hardens at room temperature post-sintering through the formation of Guinier-Preston (GP) Zones.

Application

- Primary Application: The most successful application for PM aluminum alloys is camshaft bearing-caps for overhead camshaft engines, primarily driven by weight savings and the ability to produce precise and consistent net-shape products via PM.

- Additional Applications: PM aluminum alloys find applications in hand tools, recreational equipment, and other structural components where lightweight materials are advantageous.

Microstructure

- Al-Cu Alloy System: The most popular production material displays a matrix of alpha-aluminum with minor levels of precipitates. The GP zones, which are Cu-rich “plates” on {100} planes of the fcc aluminum matrix, cannot be resolved using a light microscope. Coarse CuAl2 precipitates indicate an over-aged condition and are visible by optical metallography.

Selection and Agreement

Optimal material selection requires discussion with the PM parts manufacturer to align properties and cost-effectiveness with application requirements. Agreement between purchaser and manufacturer on aspects like strength value, grade selection, chemical composition, alloying method, proof testing, typical property values, and processes is crucial to avoid misunderstandings.

Want to learn more about PM 101? Schedule a training with us!